Trusted Plant and Machinery Hire Options for Your Business Growth

In the dynamic landscape of business procedures, the requirement for reputable plant and machinery hire alternatives has actually become extremely important for continual growth and success. As services aim to maximize their sources and enhance functional performance, the decision-making process surrounding plant and equipment hire holds significant ramifications.

Benefits of Plant and Equipment Hire

Making use of plant and machinery hire solutions provides organizations an economical service to access a varied range of tools without the concern of possession. One key advantage of going with plant and machinery hire is the ability to gain access to specialized devices tailored to particular task requirements. This versatility allows businesses to effectively take on various tasks without the demand to purchase expensive equipment that might just be needed for a restricted period.

In addition, plant and machinery hire services commonly provide well-kept equipment, reducing the threat of downtime due to mechanical problems. Equipment & Plant Hire Services. This integrity makes certain that jobs remain on track and are finished within the set up duration, ultimately improving general efficiency

Furthermore, by selecting to work with plant and equipment, companies can prevent the expenses related to tools depreciation, storage, and upkeep. This maximizes funding that can be redirected in the direction of core organization tasks or bought various other locations of development. Overall, the advantages of plant and equipment hire convert to boosted functional performance, expense financial savings, and boosted task end results for services seeking to optimize their sources.

Variables to Take Into Consideration Prior To Renting

Before participating in plant and equipment hire solutions, companies ought to carefully assess several vital aspects to make sure optimal decision-making and effective job results. It is vital to examine the specific needs of the job to determine the type and dimension of devices needed. Take into consideration elements such as work, job period, and any type of specialized attributes required. Second of all, organizations should assess the online reputation and integrity of the plant and machinery hire firm. Investigating consumer evaluations, looking for accreditations, and examining the maintenance methods of the rental company can assist guarantee the tools's quality and performance. Furthermore, it is crucial to think about the total cost implications of leasing tools, consisting of rental fees, transportation expenses, insurance, and prospective problems. Reviewing the total cost against the task budget is important to prevent any kind of economic setbacks. Lastly, organizations need to review the rental agreement thoroughly, making sure clearness on terms, upkeep duties, and liability issues. By taking into consideration these factors before renting plant and equipment, organizations can make educated choices that contribute to effective project execution - you could try this out Equipment & Plant Hire Services.

Popular Plant and Machinery Options

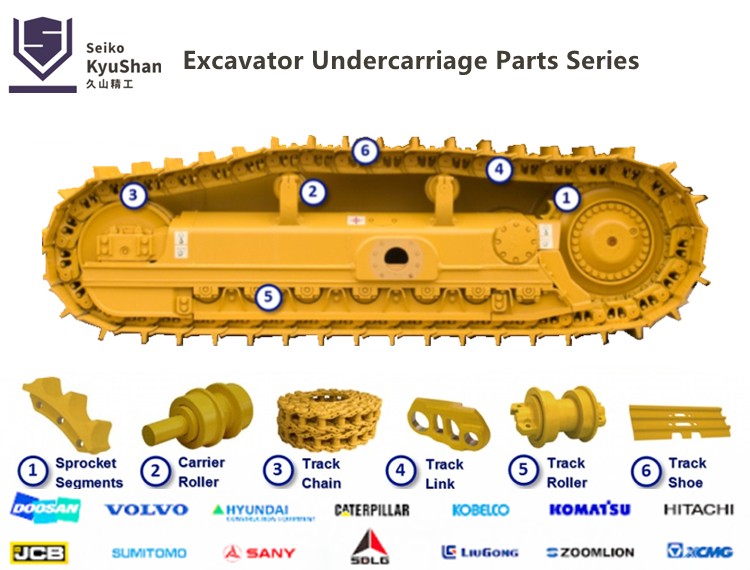

Considering the details demands and factors reviewed before engaging in plant and equipment hire services, it is important to discover the prominent alternatives offered in the marketplace that can satisfy differing company demands and add to predict success. Excavators are versatile makers suitable for a large range of jobs, from digging trenches to land clearing up. They come in numerous sizes to fit various project ranges. Skid-steer loaders are manoeuvrable and compact, excellent for building websites with limited room. Boom lifts are essential for jobs calling for employees to get to elevated areas safely. Telescopic trainers are useful for raising materials to elevations and ranges that conventional forklifts can not get to. Unload trucks are crucial for transferring materials on building and construction sites successfully. Furthermore, scissor lifts provide a secure platform for workers and devices when functioning at heights. These prominent plant and equipment alternatives offer companies the versatility and capacities needed to total jobs properly.

Tips for Optimizing Rental Effectiveness

To optimize rental performance when utilizing plant and equipment hire solutions, businesses can carry out tactical administration practices. Furthermore, organizing devices services in advance can assist in safeguarding the required equipment at the right time, avoiding hold-ups in project timelines.

Educating employees on the correct operation of the equipment can likewise contribute to improving efficiency and reducing the threat of mishaps or damages. By following these tips, businesses can simplify their rental procedures and enhance performance when making use of plant and equipment hire services.

Affordable Hiring Approaches

Comparing quotes from different plant and equipment hire firms can aid organizations locate the most competitive rates. By implementing these cost-effective hiring methods, companies can make best use of the advantages of plant and machinery hire while remaining within their spending plan restraints.

Final Thought

In verdict, plant and equipment hire can offer numerous advantages for businesses aiming to grow and increase their operations. By taking into consideration elements such as rental prices, devices schedule, and maintenance requirements, organizations can make informed choices when choosing the ideal machinery for their demands. With a broad array of options offered for hire, businesses can maximize effectiveness and performance while keeping expenses in check. Implementing economical hiring approaches can even more boost the worth of leasing plant and equipment for business growth.

Utilizing plant and machinery hire solutions supplies businesses an affordable option to access a diverse range of equipment without the burden of possession.In addition, by picking to work with plant and equipment, services can avoid the costs linked with devices depreciation, storage, and upkeep. Generally, the benefits of plant and equipment hire equate to improved functional performance, price financial savings, and boosted task results for services seeking to optimize their sources.

Before involving in plant and equipment hire services, organizations must thoroughly evaluate a number of vital aspects to guarantee optimum decision-making and successful task results.Considering the particular requirements and aspects talked about prior to engaging in plant and equipment hire solutions, it is necessary to discover the prominent alternatives available in the market that can fulfill varying service demands and contribute to project success.